Versatile Allies: Exploring the Materials Compatible with Carbide Burrs

Share

Introduction:

Carbide burrs are renowned for their versatility and durability, making them indispensable tools across various industries and applications. One of the key factors contributing to their widespread use is their compatibility with a wide range of materials, from metals and alloys to composites and ceramics. In this comprehensive blog post, we'll delve into the materials that carbide burrs can be used on, highlighting their adaptability and effectiveness in tackling diverse machining and fabrication tasks.

Exploring Material Compatibility:

1. Metals and Alloys:- Carbide burrs excel in machining metals and alloys, including steel, stainless steel, aluminum, brass, and copper.

- They are capable of shaping, deburring, and grinding these materials with precision and efficiency, making them indispensable tools in metalworking and fabrication.

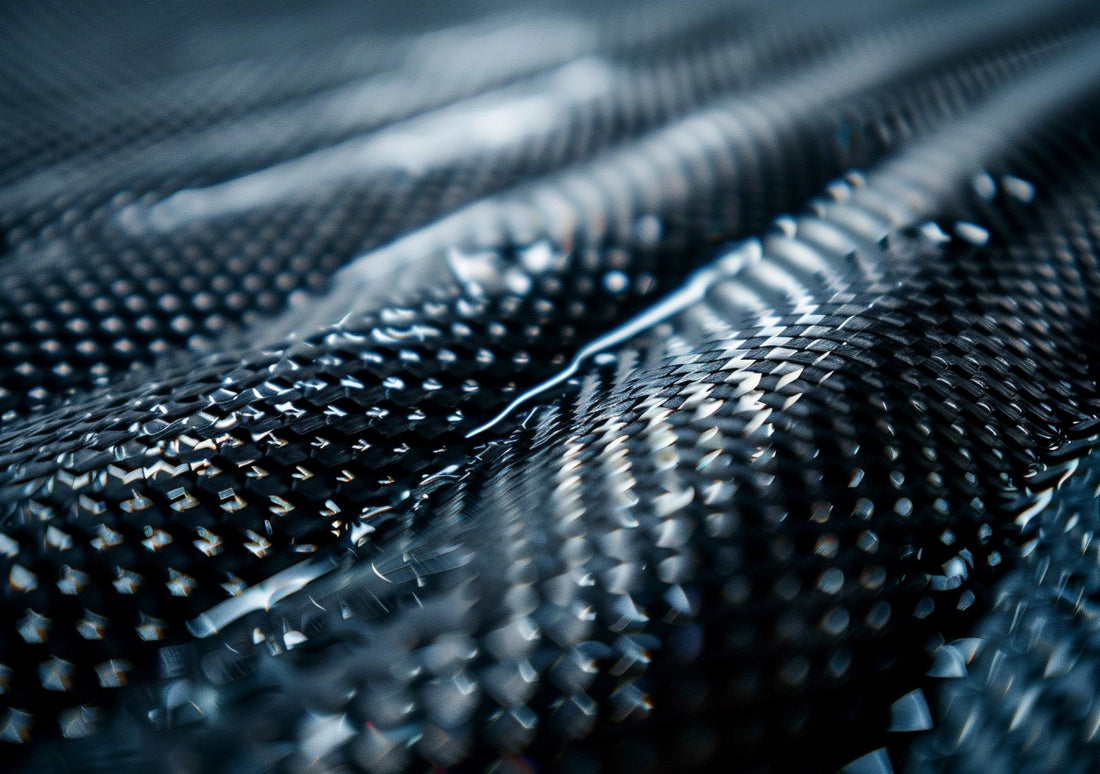

- Carbide burrs are well-suited for machining composite materials such as carbon fiber, fiberglass, and laminates.

- They offer exceptional cutting performance and durability when shaping and trimming composite components in industries such as aerospace, automotive, and marine.

- Carbide burrs can effectively machine a variety of plastics and polymers, including acrylics, PVC, nylon, and polyethylene.

- They provide clean and precise cuts, making them ideal for shaping, drilling, and finishing plastic components in industries such as electronics, signage, and consumer goods.

- While more challenging to machine, carbide burrs can be used on ceramics, porcelain, and stone materials with the appropriate techniques and tooling.

- They are employed in applications such as engraving, sculpting, and detailing ceramic tiles, pottery, and stone countertops with precision and control.

Conclusion:

Carbide burrs are versatile tools capable of machining a wide range of materials, from metals and alloys to composites, plastics, and ceramics. Their compatibility with diverse materials, coupled with their exceptional cutting performance and durability, makes them indispensable in industries ranging from metalworking and fabrication to aerospace, automotive, and beyond. By harnessing the versatility of carbide burrs, manufacturers, craftsmen, and hobbyists can achieve superior results in their machining and fabrication endeavors across a multitude of materials.