The impact of CNC ID & OD Turning Toolholders on reducing downtime and increasing machine uptime in manufacturing operations

Share

Introduction

Manufacturing operations rely on various technologies to produce high-quality products efficiently. One of the most critical components is the CNC ID & OD turning toolholder. This toolholder plays a significant role in reducing downtime and increasing machine uptime in manufacturing operations. This blog post will explore the impact of CNC ID & OD turning toolholders on reducing downtime and increasing machine uptime in manufacturing operations.

Importance of CNC ID & OD Turning Toolholders

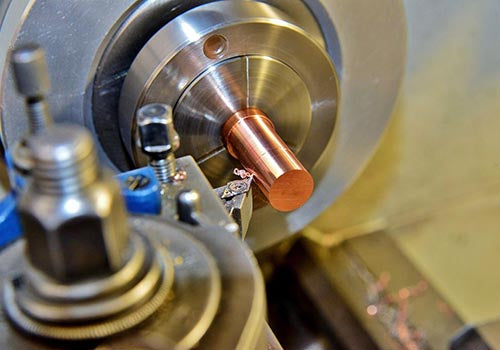

CNC ID & OD turning toolholders are essential in the manufacturing industry because they hold and secure the cutting tool in place. The cutting tool is the part of the machine that does the actual cutting, shaping, and forming of the material. Without a properly functioning toolholder, the cutting tool can become loose, resulting in poor quality work, damage to the machine, and even injury to the operator.

The design of CNC ID & OD turning toolholders allows for easy and quick changes of cutting tools, which is critical in manufacturing operations. In addition, these toolholders can handle high-speed cutting and heavy loads, which increases machine uptime and productivity. The use of high-quality CNC ID & OD turning toolholders can significantly reduce downtime and increase machine uptime, which is essential for any manufacturing operation.

Impact of CNC ID & OD Turning Toolholders on Downtime Reduction

Downtime is a significant problem in manufacturing operations. It can result in lost production time, missed deadlines, and decreased profits. One of the leading causes of downtime is tool breakage or failure. CNC ID & OD turning toolholders can significantly reduce downtime by minimizing tool breakage or failure.

CNC ID & OD turning toolholders are designed to securely hold and support the cutting tool, reducing the likelihood of breakage or failure. Additionally, these toolholders can handle high-speed cutting and heavy loads, which can cause tool breakage or failure with inferior toolholders. By using high-quality CNC ID & OD turning toolholders, manufacturing operations can significantly reduce downtime and increase productivity.

Impact of CNC ID & OD Turning Toolholders on Machine Uptime

Machine uptime is essential in manufacturing operations. It is the amount of time that a machine is available and operational for production. High machine uptime means that the machine is running efficiently, and production is at its maximum. CNC ID & OD turning toolholders can significantly increase machine uptime in manufacturing operations.

The design of CNC ID & OD turning toolholders allows for quick and easy tool changes, which reduces the time it takes to switch between tools. Additionally, these toolholders can handle high-speed cutting and heavy loads, which increases the machine's efficiency and productivity. By using high-quality CNC ID & OD turning toolholders, manufacturing operations can significantly increase machine uptime and maximize production.

Conclusion

CNC ID & OD turning toolholders are essential components in manufacturing operations. They play a significant role in reducing downtime and increasing machine uptime, which is critical for any manufacturing operation. High-quality CNC ID & OD turning toolholders can minimize tool breakage or failure, increase machine efficiency and productivity, and ultimately maximize production. By investing in high-quality CNC ID & OD turning toolholders, manufacturing operations can improve their bottom line and stay competitive in the industry.