Recognizing the Signs: How to Determine When a Carbide Burr Needs Replacement

Share

Introduction:

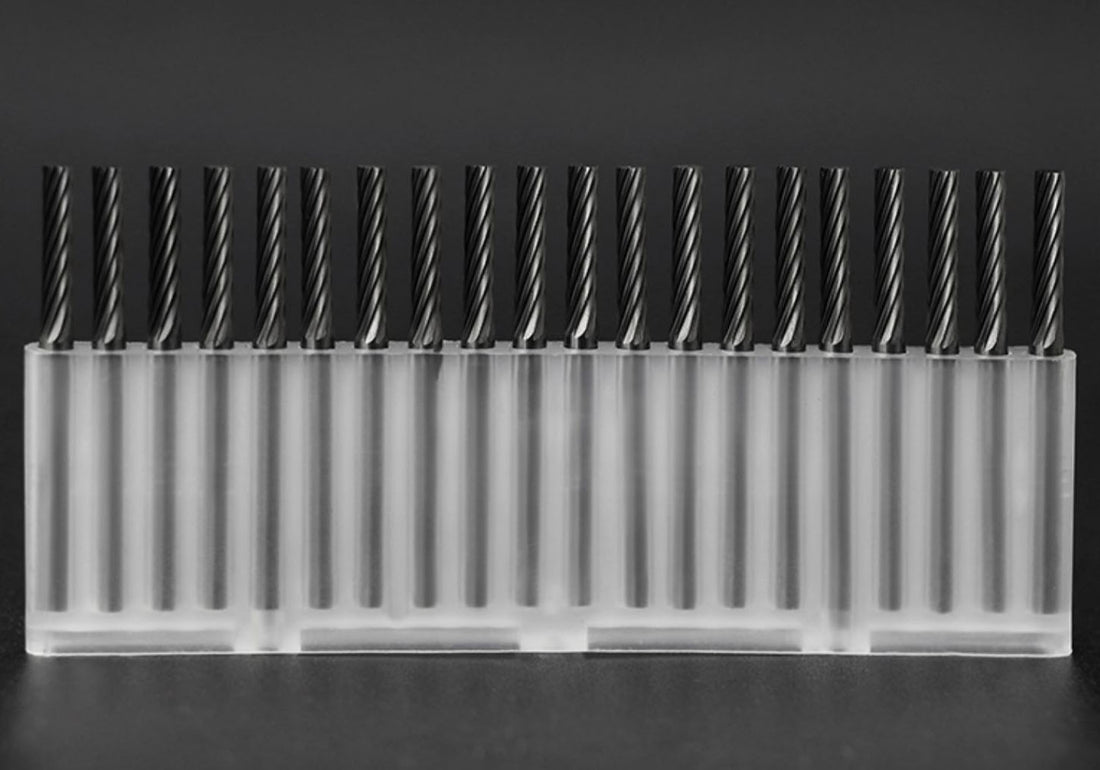

Carbide burrs are essential tools in machining and fabrication, but like any tool, they have a finite lifespan. Recognizing when a carbide burr needs replacing is crucial to maintaining productivity, quality, and safety in machining operations. In this informative blog post, we'll explore the common signs and indicators that suggest a carbide burr is nearing the end of its usable lifespan, empowering craftsmen, machinists, and hobbyists to make informed decisions about tool replacement.

Identifying Signs of Wear:

1. Dull Cutting Performance:- One of the most obvious signs that a carbide burr needs replacing is a noticeable decline in cutting performance.

- If the burr struggles to cut through material, produces rough surfaces, or generates excessive heat, it may be time for a replacement.

- Inspect the cutting edges of the carbide burr regularly for signs of chipping, cracking, or other damage.

- Any visible damage to the cutting edges compromises cutting efficiency and can lead to poor surface finish or dimensional inaccuracies in machined parts.

- A sudden increase in vibration or noise during machining operations can indicate excessive wear or damage to the carbide burr.

- Unusual vibrations or noises may suggest that the burr is no longer cutting effectively and should be replaced to prevent further damage to the workpiece or machinery.

- Keep track of the tool life of carbide burrs based on usage and machining conditions.

- If a carbide burr consistently wears out faster than expected or reaches its expected tool life prematurely, it may indicate a need for replacement or reevaluation of machining parameters.

Best Practices for Replacement:

1. Regular Inspection and Maintenance:- Implement a regular inspection and maintenance schedule to monitor the condition of carbide burrs and identify signs of wear or damage early.

- Prompt replacement of worn or damaged burrs can help prevent costly downtime and ensure consistent machining performance.

- Invest in high-quality carbide burrs from reputable manufacturers to ensure durability, performance, and reliability.

- Quality assurance measures such as batch testing and certification can provide confidence in the performance and consistency of carbide burrs.

Conclusion:

Knowing when to replace a carbide burr is essential for maintaining machining efficiency, quality, and safety. By recognizing the signs of wear and damage, implementing regular inspection and maintenance practices, and investing in high-quality tools, craftsmen, machinists, and hobbyists can maximize the performance and longevity of their carbide burrs, ensuring optimal results in their machining and fabrication endeavors.