Frequently Asked Questions About CNC ID & OD Turning Toolholders Answered

Share

If you are new to CNC machining, or just looking to expand your knowledge, you may have some questions about ID and OD turning toolholders. In this blog post, we aim to answer some of the most frequently asked questions about CNC ID and OD turning toolholders.

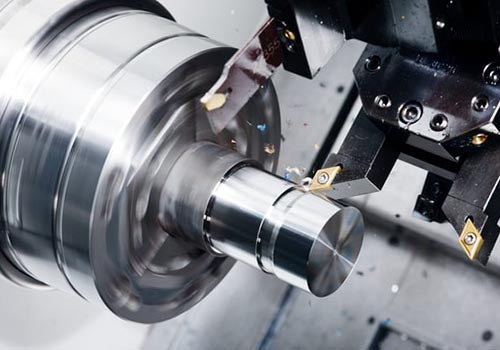

Introduction to CNC ID and OD Turning Toolholders

In the CNC machining process, toolholders are an essential part as they hold the cutting tool in place and allow for precise machining. A toolholder is a device that holds the cutting tool in a fixed position and provides a means for orientation and adjustment. The primary function of a toolholder is to ensure that the cutting tool is in the correct position and orientation to produce the desired results.

What is ID and OD Turning?

ID turning, or internal diameter turning, is the process of machining the inside of a workpiece, such as a hole or bore. OD turning, or outside diameter turning, is the process of machining the outside of a workpiece, such as a shaft or cylinder. Both ID and OD turning require different types of toolholders to hold the cutting tool in place.

What is the Difference Between ID and OD Toolholders?

The main difference between ID and OD toolholders is the location of the cutting tool. ID toolholders hold the cutting tool on the inside of the toolholder, while OD toolholders hold the cutting tool on the outside of the toolholder. ID toolholders are typically used for internal machining operations, while OD toolholders are used for external machining operations.

How Do I Choose the Right Toolholder for My Machining Operation?

Choosing the right toolholder for your machining operation depends on several factors, including the type of material you are machining, the size of the workpiece, and the required precision. It is important to choose a toolholder that is compatible with your CNC machine and cutting tool. Consult with a machining expert or tooling supplier to determine the best toolholder for your specific application.

How Do I Maintain My Toolholder?

Proper maintenance of your toolholder is essential to ensure its longevity and performance. Regular cleaning of the toolholder is necessary to prevent the accumulation of debris and dirt, which can harm the toolholder's performance. Inspect the toolholder for any signs of wear and tear or damage. Lubricate the toolholder as required to keep it in good working condition. If you notice any signs of damage or wear, replace the toolholder immediately.

Conclusion

CNC ID and OD turning toolholders are crucial components of the CNC machining process. By understanding the differences between ID and OD toolholders and how to choose the right toolholder for your application, you can improve the efficiency and precision of your machining operations. Proper maintenance of the toolholder is also critical to ensure its longevity and performance. If you have any further questions about toolholders or CNC machining in general, consult with a machining expert or tooling supplier for personalized advice.