Why CNC ID & OD Turning Toolholders are Crucial to Your Machining Operation

Share

Introduction

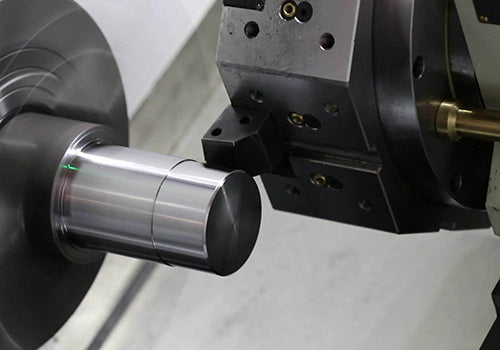

As a machinist, you are always looking for ways to improve your machining operation. One crucial component that often gets overlooked is the CNC ID and OD turning toolholder. In this blog post, we will discuss why these toolholders are crucial to your machining operation.

Improved Accuracy

One of the main benefits of using CNC ID and OD turning toolholders is improved accuracy. When machining parts, the cutting tool must be held securely in place to ensure precision and accuracy. CNC ID and OD turning toolholders are designed to hold the cutting tool firmly, which minimizes the amount of vibration during the machining process. This, in turn, leads to improved accuracy, as there is less chance of the cutting tool deflecting or moving during operation. Improved accuracy is especially important when working with tight tolerances or complex parts. By using CNC ID and OD turning toolholders, you can achieve the level of precision required for high-quality parts.

Increased Productivity

Another benefit of using CNC ID and OD turning toolholders is increased productivity. These toolholders are designed to be quick and easy to change out, which means that you can switch between tools quickly and efficiently. This allows you to complete jobs faster and with less downtime, which ultimately leads to increased productivity and profitability. With faster tool changes, you can spend more time machining parts and less time changing tools. This can help you meet tight production deadlines and increase your output.

Extended Tool Life

CNC ID and OD turning toolholders can also help to extend the life of your cutting tools. By securely holding the cutting tool in place, there is less chance of the tool becoming damaged or worn prematurely. Additionally, some toolholders are designed to incorporate coolant delivery, which can help to reduce heat buildup and prolong tool life even further. With longer tool life, you can save money on tool replacement costs and reduce downtime for tool changes.

Conclusion

In conclusion, CNC ID and OD turning toolholders are a crucial component of your machining operation. They offer improved accuracy, increased productivity, and extended tool life, all of which contribute to a more efficient and profitable operation. If you haven't already, consider upgrading your toolholders to see the benefits for yourself. Investing in high-quality CNC ID and OD turning toolholders can pay off in the long run through improved quality, increased productivity, and reduced costs.