Understanding the Role of CNC Inserts in Precision Manufacturing

Share

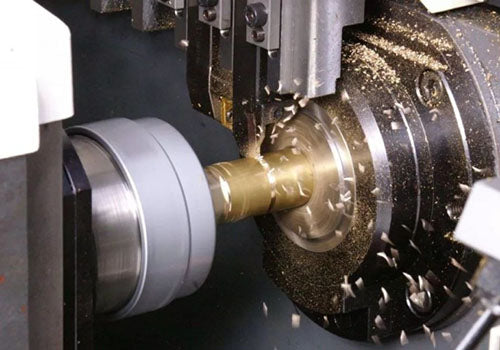

Precision manufacturing is essential for various industries, such as aerospace, automotive, and medical devices, to name a few. One of the most critical components in precision manufacturing is CNC (Computer Numerical Control) machines. These machines are widely used to produce complex and accurate parts with high repeatability. To achieve this level of precision, various components are used in CNC machines, and one of the most critical components is the CNC insert.

What are CNC Inserts?

CNC inserts are replaceable cutting tips that are used in CNC machines to shape, cut, or drill a workpiece. They are made of hard materials like tungsten carbide, ceramic, or diamond, which can withstand high pressure and temperatures encountered during the cutting process. The inserts come in various shapes and sizes, depending on the specific application.

The Importance of CNC Inserts

CNC inserts play a crucial role in precision manufacturing by ensuring accuracy, consistency, and efficiency. They provide a sharp cutting edge that maintains its shape and size, ensuring that the workpiece is cut precisely to the desired specifications. The use of CNC inserts also reduces downtime, as they can be easily replaced when worn out, without having to replace the entire cutting tool. This makes CNC machining more cost-effective and efficient.

Types of CNC Inserts

There are various types of CNC inserts, each designed for a specific application. Some of the most common types include:

Turning Inserts

These are used for turning operations, where the workpiece rotates while the cutting tool moves parallel to the axis of rotation. Turning inserts come in various shapes, including square, round, triangular, and diamond-shaped, depending on the specific application.

Milling Inserts

These are used for milling operations, where the cutting tool rotates while the workpiece is held stationary. Milling inserts come in various shapes and sizes, including square, round, and octagonal, depending on the specific application.

Drilling Inserts

These are used for drilling operations, where a hole is drilled into a workpiece. Drilling inserts come in various shapes and sizes, including round and square, depending on the specific application.

Grooving Inserts

These are used for grooving and parting operations, where a narrow and deep cut is required. Grooving inserts come in various shapes and sizes, including square, round, and triangular.

Threading Inserts

These are used for threading operations, where a thread is cut onto a workpiece. Threading inserts come in various shapes and sizes, including triangular, round, and partial profile.

Choosing the Right CNC Insert

Choosing the right CNC insert is essential to achieve the desired results. It is necessary to consider various factors, such as material type, machining process, desired finish, and cutting speed. The right CNC insert can help you achieve optimal performance and longevity, while the wrong insert can result in poor quality, increased downtime, and higher costs.

Conclusion

In conclusion, CNC inserts are critical components in precision manufacturing. Their use ensures accuracy, consistency, and efficiency, making CNC machining more cost-effective and efficient. Understanding the role of CNC inserts and choosing the right one for your specific application can help you achieve optimal results and stay ahead of the competition.