The Advantages of Using CNC ID & OD Turning Toolholders in a Variety of Industries and Applications

Share

Introduction

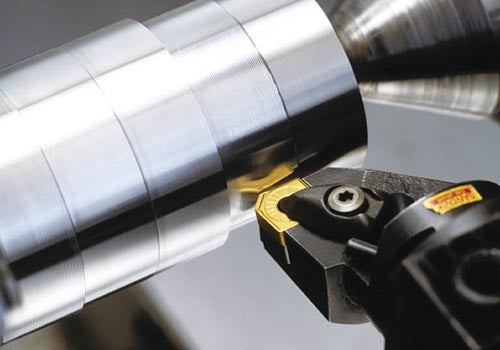

CNC ID & OD turning toolholders are used in a wide range of industries, including aerospace, medical, automotive, and many others. These toolholders offer a variety of advantages over traditional tooling methods, including increased precision, reduced cycle times, and improved surface quality. In this blog post, we will explore the advantages of using CNC ID & OD turning toolholders in different industries and applications.

Aerospace Industry

The aerospace industry is one of the most demanding industries in terms of precision and quality. CNC ID & OD turning toolholders are widely used in this industry to produce the complex components required for aircraft engines, landing gears, and other critical parts. These toolholders offer several advantages, including:

- Increased precision: CNC turning toolholders can produce highly precise parts with tolerances of up to 0.001mm. This level of precision is essential in the aerospace industry, where even small deviations can have catastrophic consequences.

- Reduced cycle times: CNC turning toolholders can produce parts much faster than traditional tooling methods. This is because they can perform multiple operations in a single setup, reducing the number of times the part needs to be repositioned.

- Improved surface quality: CNC turning toolholders can produce parts with a much smoother surface finish than traditional tooling methods. This is because they can make very small cuts with high accuracy, resulting in a more uniform surface.

Medical Industry

The medical industry is another industry where precision is paramount. CNC ID & OD turning toolholders are widely used in this industry to produce medical implants, prosthetics, and other critical components. These toolholders offer several advantages, including:

- Increased precision: CNC turning toolholders can produce parts with tolerances of up to 0.001mm, making them ideal for producing complex medical components.

- Reduced cycle times: CNC turning toolholders can produce parts much faster than traditional tooling methods, reducing the lead time for critical medical components.

- Improved surface quality: CNC turning toolholders can produce parts with a very smooth surface finish, which is essential for medical implants and prosthetics.

Automotive Industry

The automotive industry requires high volumes of parts to be produced quickly and efficiently. CNC ID & OD turning toolholders are widely used in this industry to produce components such as gears, shafts, and bearings. These toolholders offer several advantages, including:

- Increased precision: CNC turning toolholders can produce highly precise parts with tolerances of up to 0.001mm. This level of precision is essential for automotive components that need to fit together perfectly.

- Reduced cycle times: CNC turning toolholders can produce parts much faster than traditional tooling methods, reducing the lead time for critical components.

- Improved surface quality: CNC turning toolholders can produce parts with a very smooth surface finish, which is important for automotive components that need to be durable and resistant to wear and tear.

Conclusion

CNC ID & OD turning toolholders offer a variety of advantages over traditional tooling methods. They can produce highly precise parts with a smooth surface finish, and they can do so much faster than traditional methods. These advantages make them ideal for use in a variety of industries, including aerospace, medical, automotive, and many others. If you are looking for a tooling method that offers precision, speed, and quality, CNC ID & OD turning toolholders are an excellent option to consider.