How CNC ID & OD Turning Toolholders can increase the lifespan of cutting tools and reduce tool wear

Share

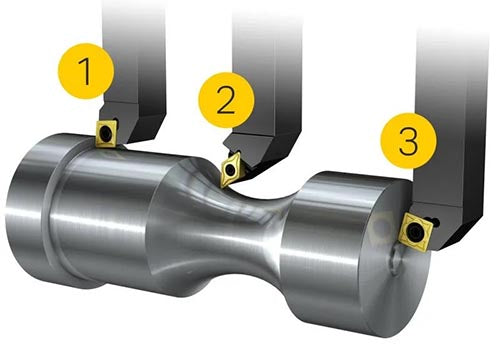

Cutting tools are a significant investment for any machining operation, and it is essential to ensure that they last as long as possible while maintaining peak performance. One way to achieve this is by using CNC ID and OD turning toolholders. These toolholders provide a range of benefits that can help increase the lifespan of cutting tools and reduce tool wear.

Increased Stability

CNC ID and OD turning toolholders provide increased stability, which is essential for cutting tools to perform optimally. Stability is achieved by holding the cutting tool securely in place, reducing the amount of vibration and chatter that can occur during machining. Vibration and chatter can cause tool wear and reduce the lifespan of cutting tools.

With increased stability, cutting tools are less likely to suffer from these issues, resulting in longer tool life and better machining performance. As a result, machining operations can achieve more consistent and efficient results, ultimately leading to improved productivity and profitability.

Improved Coolant Flow

Coolant flow is another critical factor in increasing the lifespan of cutting tools. CNC ID and OD turning toolholders are designed to allow for improved coolant flow to the cutting area. This increased coolant flow helps to remove chips and debris from the cutting area, reducing the possibility of chip buildup and tool wear.

Additionally, the improved coolant flow helps to cool the cutting tool, further reducing the risk of tool wear and increasing its lifespan. The cutting tool remains cooler, which reduces thermal expansion and prolongs the cutting edge's life. This results in reduced downtime and maintenance costs.

Reduced Runout

Runout is the measurement of how much a rotating tool deviates from its true axis of rotation. High levels of runout can cause tool wear and reduce the lifespan of cutting tools. CNC ID and OD turning toolholders are designed to reduce runout, providing a more accurate and consistent machining process.

This reduction in runout helps to ensure that cutting tools are operating at their optimal level, resulting in longer tool life and better machining performance. The reduction in runout also ensures that there is no unnecessary stress on the cutting tool, which can cause fatigue and breakage.

Conclusion

CNC ID and OD turning toolholders are an excellent investment for any machining operation. By providing increased stability, improved coolant flow, and reduced runout, these toolholders can help increase the lifespan of cutting tools and reduce tool wear.

By using CNC ID and OD turning toolholders, machining operations can achieve more consistent and efficient results, ultimately leading to improved productivity and profitability. With longer tool life and reduced downtime for maintenance, companies can save money in the long run, making CNC ID and OD turning toolholders a sound investment.